phone0121 507 8702 emailmail@gillcivil.com ![]()

![]()

![]()

![]()

![]()

Uncategorised

M54 - 2015

Project: M54 - Junction 3 to 4 (Both Carriageways) | Client: Costain Ltd & AMEY | Duration: 12/01/2015 - 07/03/2015 | Suppliers: AJ Wilcock Holeformers, ACCUMIX, and Titan Plant Hire Ltd

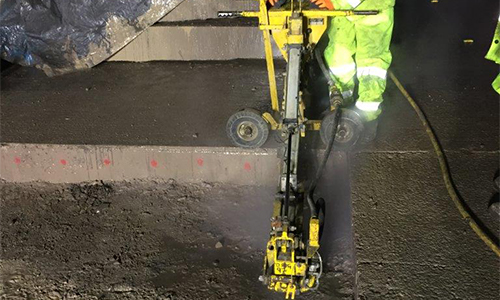

Scope: Full Depth (280mm) bay replacements in PQ-X concrete.

Details:

GCEL was appointed to carry out 2862 m2 full depth concrete repair to both carriageways of M54 between junction 3 to 5. The scope of work includes removal of existing dowelled concrete bays and reinstating using PQX (High early strength concrete) overnight. The concrete bays (4m x 5m x 280mm) were saw cut into smaller section and lifted out using vacuum lift device attached to a wheeled excavator. Type 1 formation was inspected and replaced as required, new dowel bars were drilled and installed using EZ 210B SRA drill, reinforcement placed prior to reinstating using PQX concrete mixed on site, using a volumetric mixer. To accelerate curing of concrete, heated blankets were used. Between 3-5no. concrete bays were repaired on regular basis during weekdays between working hours 22:30 to 05:00 (next morning) and up to 24 bays were repaired on weekend shifts. The carriageways were successfully open to normal traffic at 06:00 AM every morning during the project duration.

Projection Completion Date: 07/03/2015

M42 - 2014

Project: M42 - Junction 3A to 4 (North and South Carriageway) | Client: Costain Ltd and AMEY | Duration: 23/11/2013 - 21/01/2014 | Suppliers: AJ Wilcock Holeformers, ACCUMIX, and Titan Plant Hire Ltd

Scope: Full Depth (255mm) bay replacements in PQ-X concrete.

Details:

GCEL was appointed to carry out 1310 m2 full depth concrete repair to both carriageways of M42 between junctions 3A to 4. The scope of work includes removal of existing dowelled concrete bays and reinstating using PQX (High early strength concrete) overnight. The concrete bays (4m x 5m x 255mm) were saw cut into smaller section and lifted out using vacuum lift device attached to a wheeled excavator. Repairs were carried out to lean mix, new dowel bars were drilled and installed using EZ 210B SRA drill prior to reinstating using PQX concrete mixed on site, using a volumetric mixer.

To accelerate curing of concrete, heated blankets were used. Between 3-4no. concrete bays were repaired on a regular basis each night between working hours 21:00 to 05:00 (next morning). The carriageways were successfully open to normal traffic at 06:00 AM every morning during the project duration.

Project Completion Date: 21/01/14

Gatwick Airport - 2016

Project: Gatwick Airport - Pier 1 Apron and Taxiway Reconfiguration | Client: Vinci Construction UK Ltd | Duration: Oct 2014 - Jul 2016 | Suppliers: Titan Plant Hire Ltd and Lafarge Tarmac

Scope: Installation of WLC and PQC, AGL Ducting, Slot Drains and UKAS Testing

Details:

Gill Civil Engineering Ltd (GCEL), worked with Vinci Construction to construct Gatwick Airport Pier 1 Apron and Taxiway. The project was constructed over 4 phases, working both airside and landside. GCEL placed 46,000m2 of Pavement Quality Concrete (PQC) and Wet Lean Concrete (WLC); PQC depth varied from 350mm to 500mm and WLC was 150mm thick. Concrete was supplied from a nearby Lafarge Tarmac compound.

Integrated into our PQC works, we installed both AGL ducting and Gatic Slot Drainage. Due to the large scale and tight deadlines of this project, we worked on a daytime and night time shift to ensure works were completed on time.

Project Completion Date: Jul 2016

RAF Valley - 2016

Project: RAF Valley - Runway Refurbishment | Client: Northstone and Whitemountain JV | Duration: Jul 2016 - Oct 2016 | Suppliers: Titan Plant Hire Ltd

Scope: Installation of Pavement Quality Concrete (PQC), Wet Lean Concrete (WLC), V Channel and Gatic Slot Drains.

Details:

Gill Civil Engineering Ltd (GCEL) was appointed to construct the airfield pavement works using pavement quality concrete (PQC) at RAF Valley on the Isle of Anglesey. GCEL laid 26,075 m2 of 260mm thick PQC and 150 mm thick Wet Lean Concrete, Gatic slot drain, surface V-Channel drainage, along with catch bit and outlet chambers.

A majority of the paving work was programmed to be completed during bolthole (4-week airfield shutdown period). In order to meet the requirement of the project, GCEL mobilised an onsite batching plant which would ensure continuous concrete supply to day and night shifts worked to meet the programme.

Project Completion Date: Oct 2016

Welcome to Gill Civil

Gill Civil Engineering Limited has been established for over twenty years. We have utilised this time to cement strong relationships with our clients, refine our ways of working, enhance our technical capabilities and broaden our portfolio. Our range of projects encompasses aviation (both civil and military), rail, highways, utilities, infrastructure, residential, commercial, education and healthcare.

We undertake projects from £100k to £10m with a responsive and dependable infrastructure that enables us to work in partnership with our key customers and trade ethically with our supply chain.

We do this through ‘delivering excellence’ through a sector-leading quality of service delivered safely, sustainably, on time, within budget and with due diligence to the environment. This is attested to by our external registration to the stringent ISO9001, ISO14001 and OHSAS18001 international standards.

Latest News

- Gill Civil recognises Jageet Singh for excellent Health & Safety Thursday 13 April 2023

- Gill Civil Engineering completes new pathway at Romsley Playing Fields Tuesday 11 January 2022

- Gill Civil Engineering Begins Works at Walney Airfield Wednesday 05 December 2018

© All Rights Reserved Gill Civil 2018 | Part of the Gill Group Companies